"Silver-Lithium Switch" to Revolutionize Batteries

New protective layer boosts lithium metal battery performance

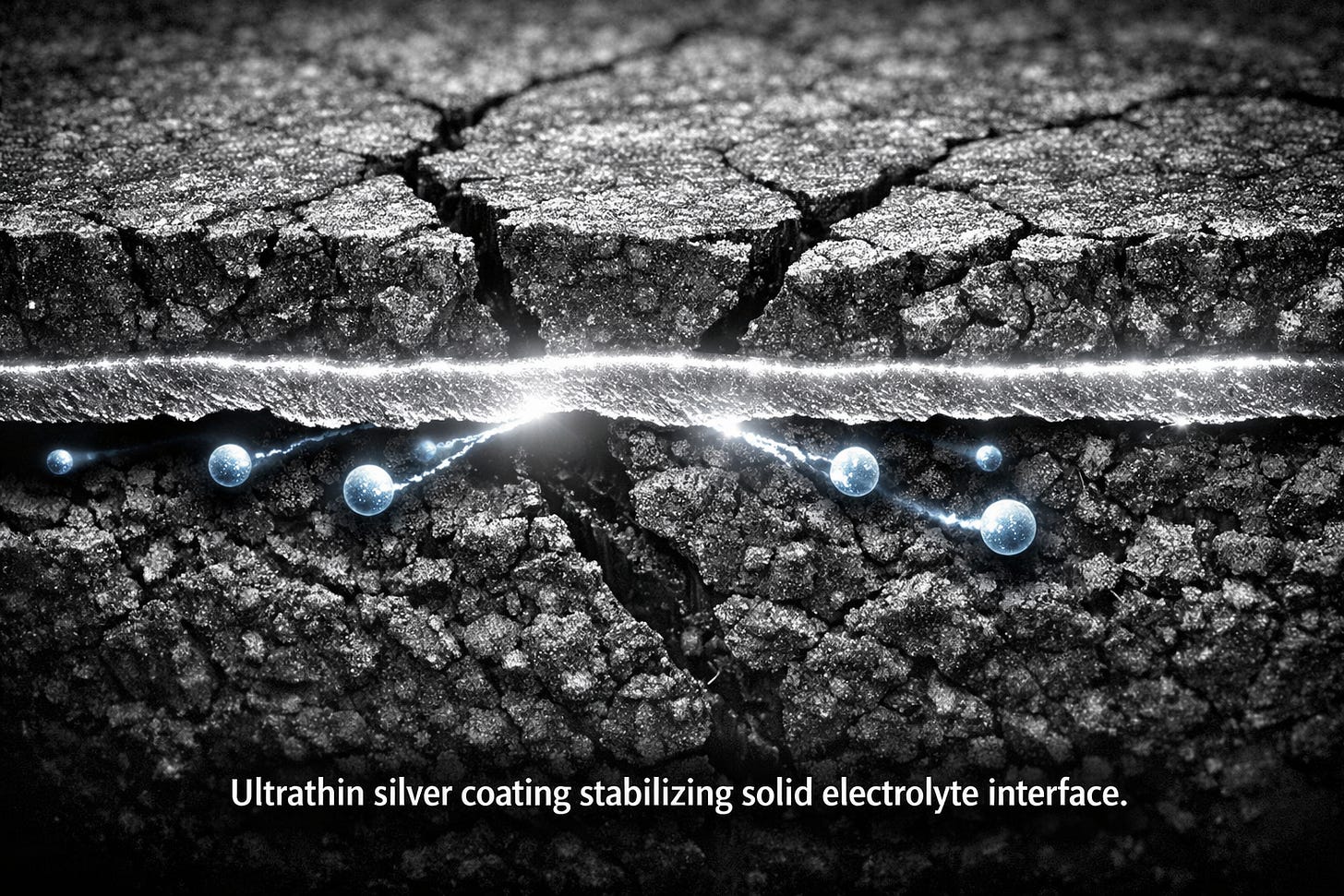

GFN – STANFORD: A team of researchers at Stanford University has unveiled a nanoscale silver coating that dramatically improves the mechanical resilience of solid-state lithium metal batteries, potentially clearing a longstanding barrier to their commercial viability. The findings — published in Nature Materials on January 16, 2026 — show that a mere few-nanometer layer of silver can make brittle ceramic electrolytes up to five times more resistant to cracking and reduce damaging lithium intrusion during fast charging.

The Stanford team — led by researchers including Xun Wendy Gu and Xin Xu — built upon earlier work identifying the microscopic origins of electrolyte imperfections to design an ultrathin silver protective layer that enhances structural integrity. As reported in Nature Materials, “the silver-treated surface became five times more resistant to cracking caused by mechanical pressure”, a key advance for solid-state systems long plagued by fracture-induced failure.

This protective layer also mitigates the tendency for lithium metal to wedge into pre-existing surface flaws, a process that accelerates crack growth and leads to irreversible degradation. According to the Stanford press release, “the silver helps seal tiny flaws and prevents lithium from causing further damage,” an effect that could significantly improve battery lifetime and safety.

Solid-state lithium metal batteries have been eyed as the next generation of energy storage due to their higher energy density, faster charging, and improved safety compared with conventional lithium-ion chemistries. However, the inherent brittleness of crystalline solid electrolytes has been a persistent obstacle, undermining commercial scalability. The new silver coating offers a relatively simple, materials-level solution to that problem.

In laboratory tests, the ultrathin silver layer not only improved fracture resistance but also made existing surface imperfections less vulnerable to lithium intrusion — a failure mode especially prominent under high-rate charge cycles. While these results are promising, researchers note that further work is needed to validate performance in full commercial cell configurations and over extended cycling.

“Ultrathin surface coatings can make the electrolyte less brittle and more stable under extreme electrochemical and mechanical conditions,” said one of the study’s lead authors, pointing to the broader potential of the approach for energy storage technologies.

If this silver-coating strategy scales effectively, it could accelerate the adoption of solid-state lithium metal batteries in electric vehicles, grid storage, and portable electronics, where higher energy content and fast charge capability are increasingly in demand.

Orignal article here

Samsung's all solid state battery is built with an Ag-C (silver - Carbon) layer. It replaces flammable liquid electrolytes with a solid electrolyte. It should be in commercial production early in 2027 for EV's. Way ahead of anything that is being tested at Stanford.

and all those batteries need graphite hence Titan Mining TII